The 12E Clock, A Warriors Guide

A comrade through the tragedies and triumph of war, for decades Chelsea Clock has been crafting specially made clocks for the United States Navy that have accompanied men to withering adventures, remote areas, surging seas and temperamental environments. Rigorous testing and the proof that the pulsing tick-tock of a Chelsea Clock would keep beating consistently and precisely above all and many tribulations were some of the requirements for a Chelsea Clock to enlist as a timekeeper for the nation’s battles.

It was the accuracy and durability of a Chelsea Clock that the government sought out when it chose to supply a large portion of its navy vessels with the Boston Based company's time instruments. As the government expected the clock went along with their men to the depths of the earth. Sometimes both companions came out unscathed from the unforgettable acts of war. And sometimes it is the clock alone that is intact, salvaged from the wreckage of war.

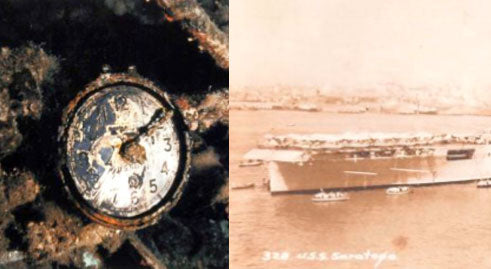

A Chelsea Clock found aboard the USS Saratoga, air craft carrier from 1920.

A Chelsea Clock found aboard the USS Saratoga, air craft carrier from 1920.

Experts at the Chelsea factory ensured the timely instrument would thrive in unexpected conditions. And before the 12E clock was packed up and shipped off to anywhere “World” it withstood internal tests that mimicked situations it could encounter endured during World War II or Vietnam.

In an interview with now retired John McCarthy, an employee that worked as a manufacturing manager for 28 years, he explained that the clock Jim Leone built was more accurate than any of its day. “In those days a mechanical clock would only keep time maybe an accuracy of only two or three minutes a day. But the 12E that Jim Leone built was plus or minus three seconds a day in accuracy,” said McCarthy who currently works for the company in a consulting role. Leone, the director of engineering during the mid 1900’s designed a clock above and beyond government requirements. The clock was required to have the utmost resilience to: various conditions, weather, sea, the sound waves of a shooting ship's gun etc. “It doesn’t take much of a shock to stop it [the escapement of a clock], and the parts are very small. But this clock was made [to go through all kinds of tests] to drop to the floor and it would still work.

McCarthy recalled several of the tests the clocks were put through before they were sent to locations he could not recall. In particular the staff placed clocks in a deep freezer cabinet with dry ice. The clocks would stay in that sealed off environment for days, with the temperature dropping to below 80 degrees below zero. The clocks would stop working as the conditions would congeal the oil; however the testament to clock’s ability to endure extreme conditions was that it would start working again once the temperature rose. The amazement was not that it only still ticked. The amazement was that the clocks kept time precisely, even after living through temperatures that most wildlife could not withstand.